Vibrodiagnostics of screw pumps

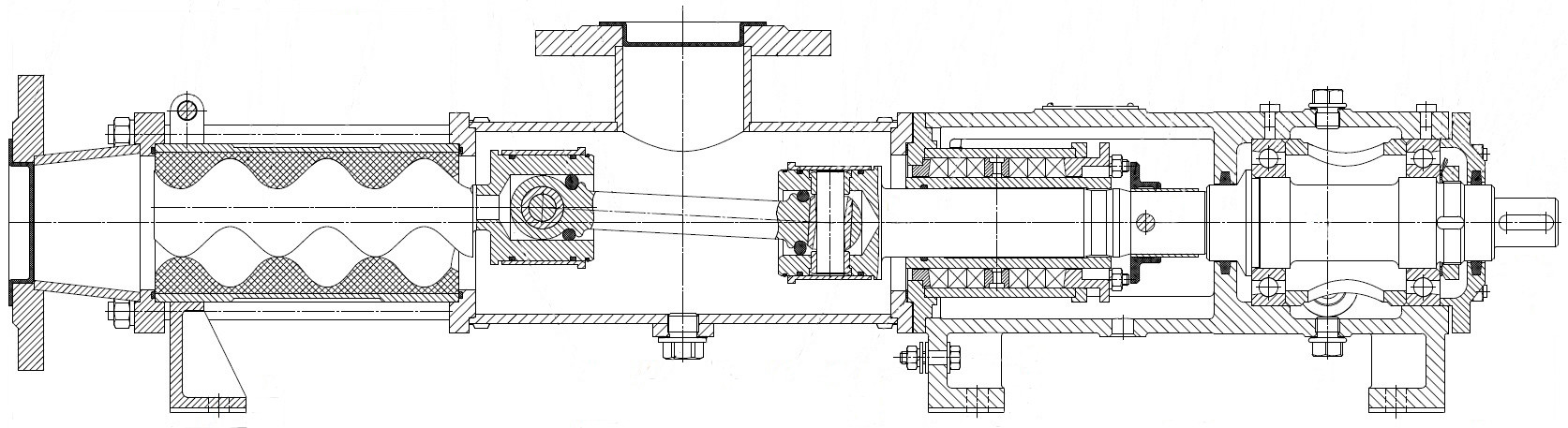

I have seen a lot in my practice, I had to work with many equipment, but I did not encounter screw pumps. They are very expensive, including in maintenance, and, accordingly, are rare. And so it happened. The problem is immediately with two pumps Н1В 20/5 - 16/5 (N = 5.5 kW, n = 1440 rpm).

I'll start with their story. They never turned on, after an indefinite time after installation, the room with them was flooded. Under one and a half meters of water stood for about a year (or maybe more, this mystery is covered in darkness), until it was time to exploit them. After pumping water out of the room, the electric motors were dried, the bearings in them were replaced, testing was performed at idle with vibration measurement (not exceeding 1 mm / s). My colleague was present at the start-up of the units, and in addition to the loud noise from the pumps, he recorded a vibration of about 17 mm / s. The pumps were stopped and taken out for repair. Repairmen washed bearings, filled grease, cleaned the inside of the pump from dirt. After decommissioning, they called me for testing.

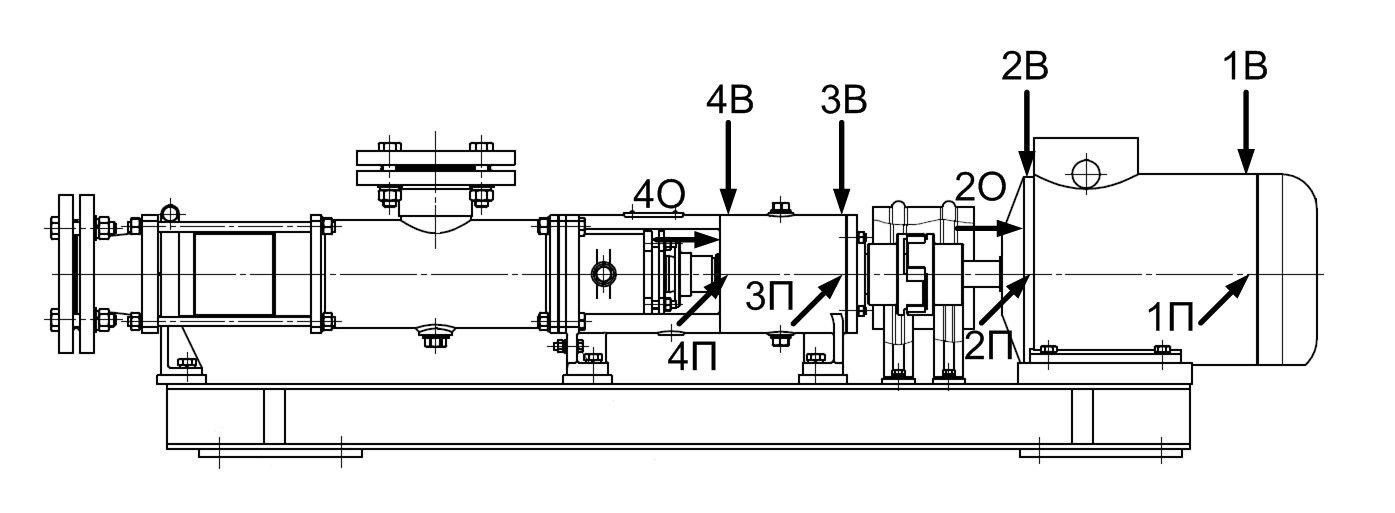

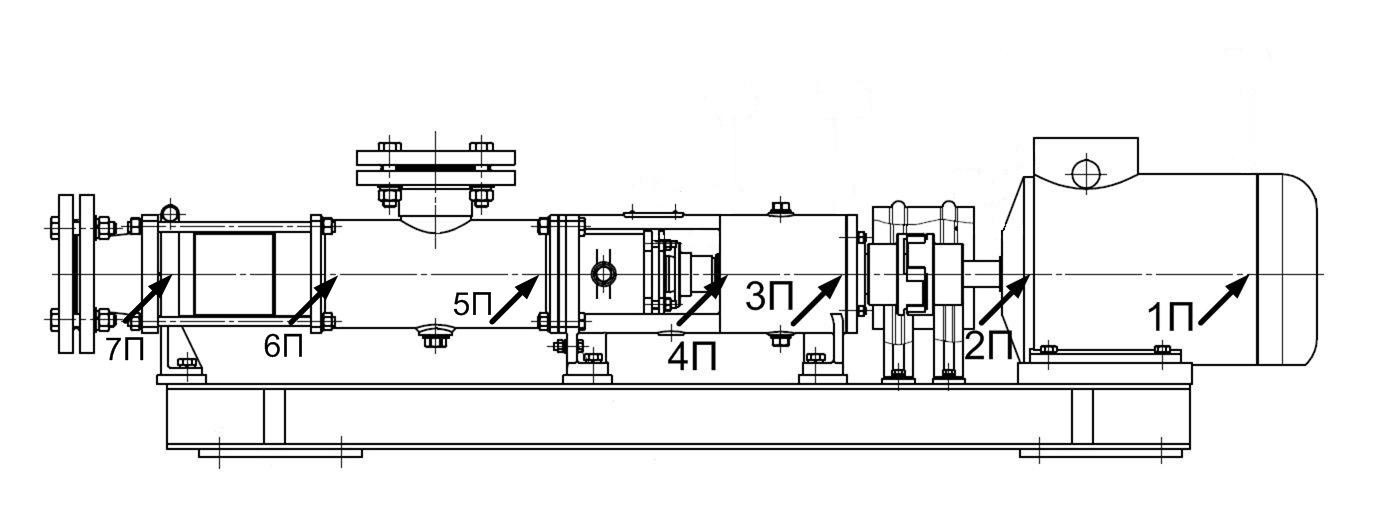

Turn on pump No. 1 and measure the vibration (RMS vibration velocity in the range of 10-1000 Hz, mm / s):

Vibration tolerance in accordance with factory documentation 2.0 mm / s. As you can see, the tolerance is greatly exceeded. The operation of the unit is accompanied by a loud noise from the pump. Additionally, I take measurements on the pump casing in the horizontal-transverse direction and compare the results for this direction.

Comparison data:

Indeed, the source of noise and vibration is the flow part of the pump. We note the negative pressure on the manometer of the suction line (arrow just below "0" - is the manometer defective?). Turn off the pump.

Proceed to turn on and measure the vibration of pump No. 2 (RMS vibration velocity in the range of 10-1000 Hz, mm / s):

The pump also works with noise, turn it off.

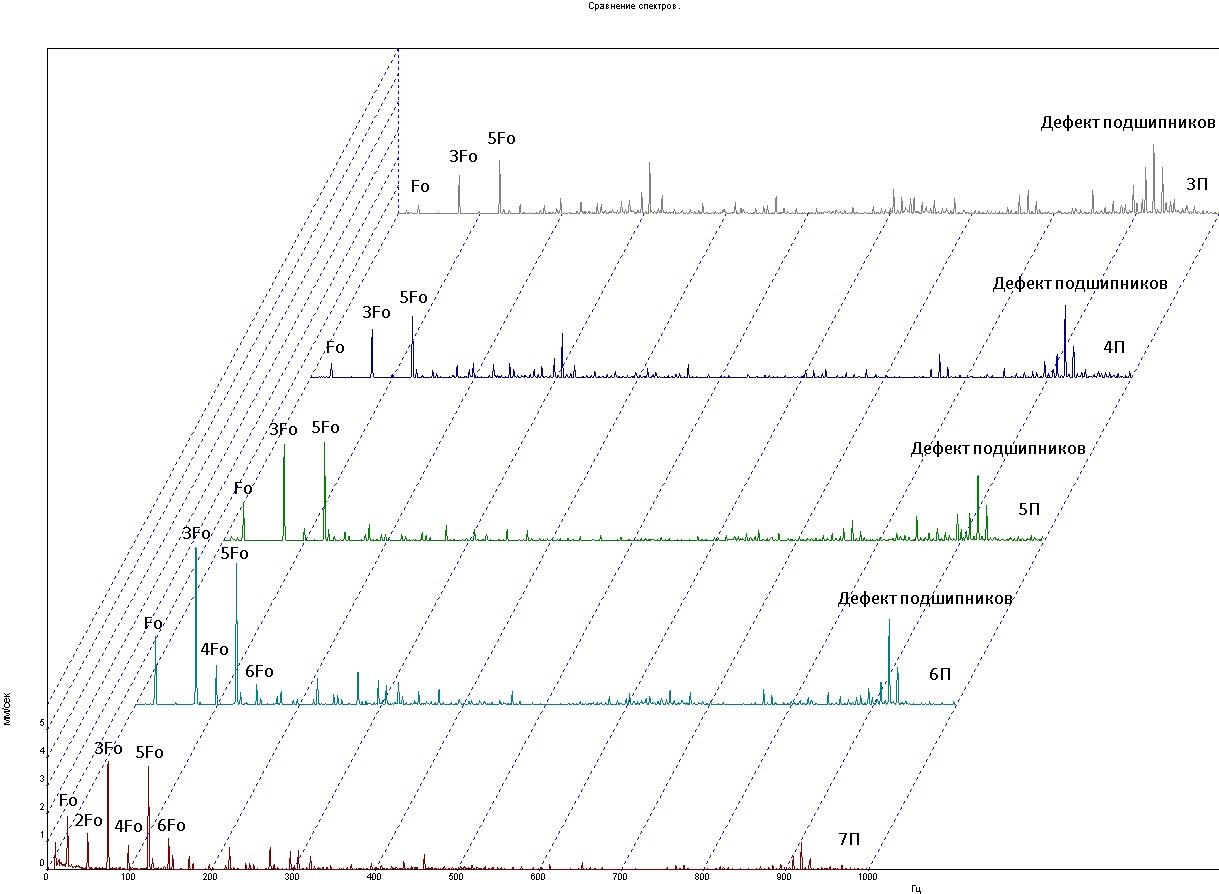

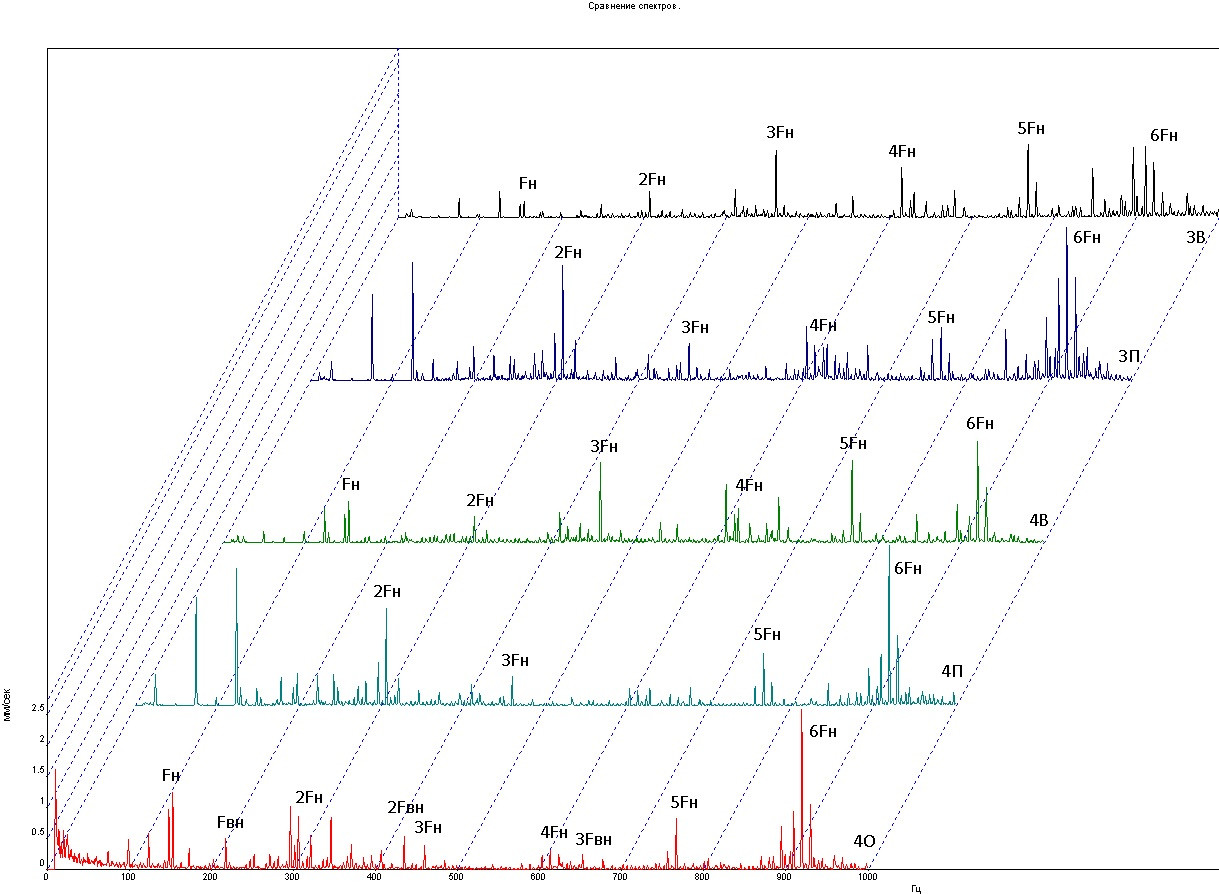

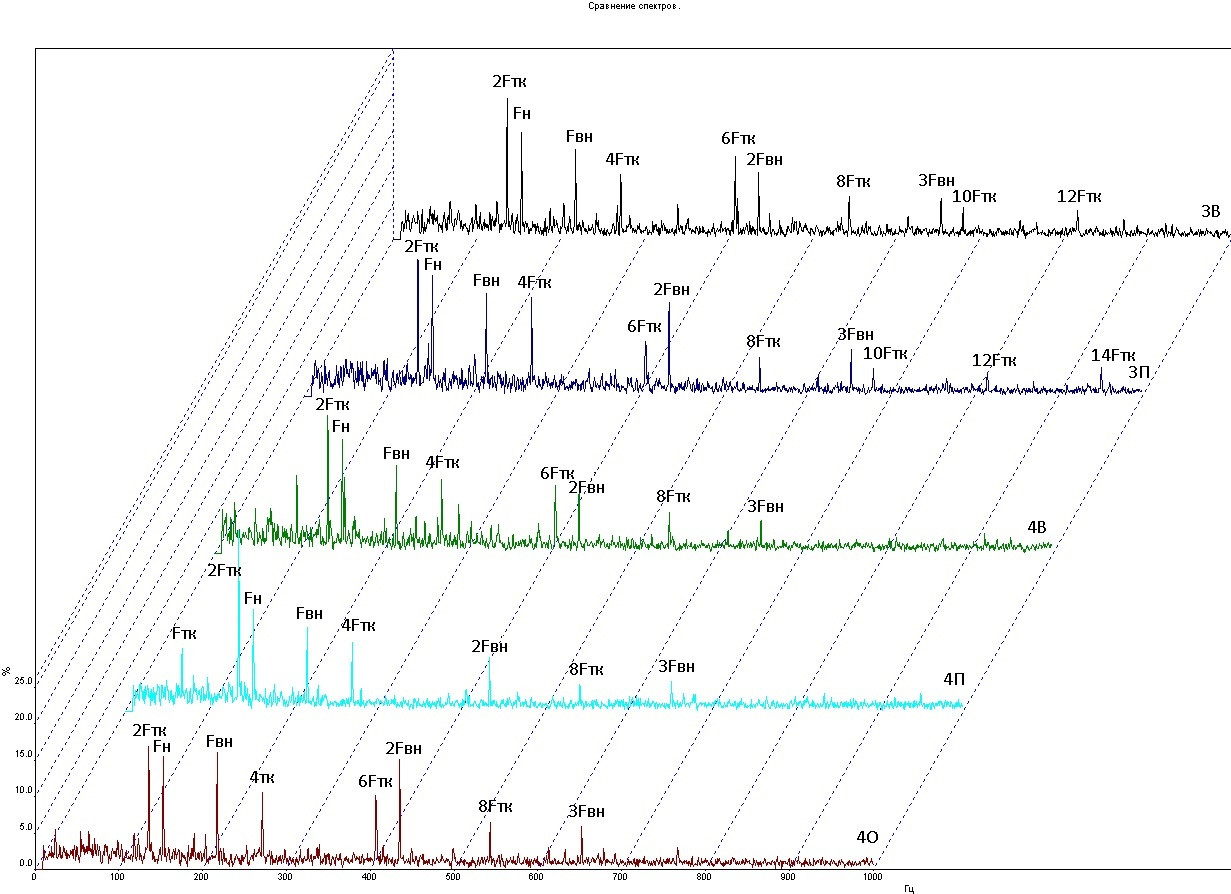

Let's move on to vibration analysis of pump No. 1. To be honest, I ran into some panic in my head. The fact is that I have no habit of giving any conclusions from a fool. I work on the basis of justification. Therefore, I had to spend a lot of time studying screw pumps. As always, there is little information on the Russian-language Internet, so I had to go over foreign articles. Looking ahead, I’ll say that I got a lot of information, but I didn’t find a concrete answer to this case. We analyze the vibrational velocity spectra of the bearings and pump housing in the horizontal-transverse direction:

The high amplitudes of the harmonics of the rotational speed Fo indicate a strong screw fight in the pump housing, which is probably caused by the instability of the screw contact with the cage surface. In my opinion, this may be due to the presence of air between the screw and the holder, or due to severe damage to the working surfaces (according to the repairmen, the surfaces of the screw and holder are ideal, but I have no habit of trusting words - I burned, I know). The vibration examination protocol reflected the following possible causes of this behavior:

- lack of pumped medium due to overlap of the suction channel;

- airness of the pump;

- air access to the pump;

- defects in the surfaces of the screw and ferrule;

- the presence of large foreign matter in the pumped medium (in the absence of filter screens at the inlet).

To determine the bearing defect, we calculated the frequencies of the bearing 46212 and analyzed the frequencies in the direct spectra of vibration velocity and spectra of the envelope of the vibration signal. When calculating the bearings, it was found that the number of rolling bodies is 15 pcs., Which indicates the installation in the housing of the foreign analog 7212 AC (46212 - 14 rolling bodies, 46212 L - 13 rolling bodies) and the following bearing frequencies were determined:

From the analysis of the given spectra, the following conclusions can be drawn:

1. The presence of a number of harmonics in the rolling frequency of rolling elements along the outer ring indicates defects in the tracks of the outer rings of the bearings. In the direct spectrum of vibration velocity, the presence of side components kFn ± nFc is noticeable, where k, n are integers. This fact is characteristic of such defects as the skew of the outer ring (with the separator wedging), and sinks on the outer ring. The presence of high levels of these components in the direct spectrum of vibration velocity indicates the development of the defect.

2. The presence of a number of harmonics of the frequency of rolling of rolling elements along the inner ring indicates defects in the tracks of the inner rings of the bearings.

3. The predominance of even harmonics of the frequency of rotation of the rolling elements is characteristic of a defect - shells, chips on the rolling elements (parity is associated with the contact of the deformed surface of the rolling element with both surfaces of the outer and inner rings).

Most likely, the water overcame the seals and got into the bearings, which led to corrosion of its internal elements.

In conclusion, I made the following recommendations:

- replace bearings No. 3, 4 of the pump;

- ensure the serviceability and operability of pressure gauges at the suction and pressure of the pump;

- check the absence of overlap of the passage on the suction line;

- check for lack of air after filling the pump;

- when repeating extraneous noise and increased vibration during pump operation, inspect its working parts and assemblies.

The vibration spectra of pump No. 2 are similar, only there are no bearing components. Envelope spectra are almost empty. Therefore, the reasons and recommendations are the same as for pump No. 1, but without complaints about the bearings.

A few days later, the pipelines on the suction lines of the pumps were dismantled and “greetings” from installation were found:

Plastic plugs with holes in the center are the cause of all problems. The diagnosis was confirmed. Regarding bearings, they did not change, but there will be an opportunity to re-defect them when testing pumps without plugs.

Как под копирку) я именно с таким насосом имел именно такую же проблему, но меня сразу насторожила модулированная составляющая обозначенная у тебя 6Fн - как правило именно так выглядит кавитация. Мне повезло, что мастер по ремонту не по-наслышке был знаком с этим явлением и знал где копать и уже к вечеру того же дня позвонил и попросил отписать в журннал на смене, что все ОК. Когда я пришел на смену, у него в руках была такая же заглушка) Для полноты картины не хватает спектров после ее извлечения. Ведь мне так и не удалось записать спектры после устранения (у ремонтников был свой Янтарь). Это совпадение наводит на мысль о том, что не плохо было бы как то систематизировать и передавать опыт. Печально, что АТЭ-шники мух не ловят. А ведь они как раз таки могли бы вести такую работу с фиксацией подобных косяков и принятием мер для того чтобы ошибка не становилась системной.