Finding condenser leaks

Поиск протечек, Акустический течеискатель

There are many ways to find suction cups in capacitors. Starting with the use of candles, soap solution, film stretching, aerosol spraying, and ending with more advanced ultrasonic devices with nozzles. Each of these methods has many disadvantages, the main of which is the time of defect localization. Not so long ago, devices of a new class appeared on the market - acoustic visualizers. The technology of overlaying data from an array of microphones onto the image from the device's camera allows you to accurately localize the source of noise even from a considerable distance. In this short article, I want to share my experience with the Fluke ii900 acoustic camera.

To identify sources of noise from static and dynamic equipment, we purchased a Fluke ii900 industrial acoustic imager.

Its main characteristics:

- 64 digital MEMS microphones;

- frequency band from 2 kHz to 52 kHz;

- the minimum frequency is 25 frames / s;

- the ability to select a frequency band;

- photo and video recording;

- touchscreen;

- operating temperature from 0 ° C to 35 ° C;

- dimensions 186 × 322 × 68 mm;

- weight 2.15 kg.

The device is very easy to use. The main drawbacks in my opinion are that the weight is too large for one-handed operation, poor ergonomics (inconvenient). Everything else is fine.

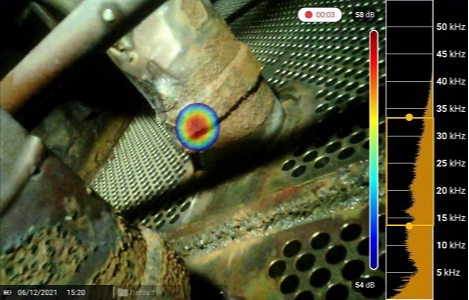

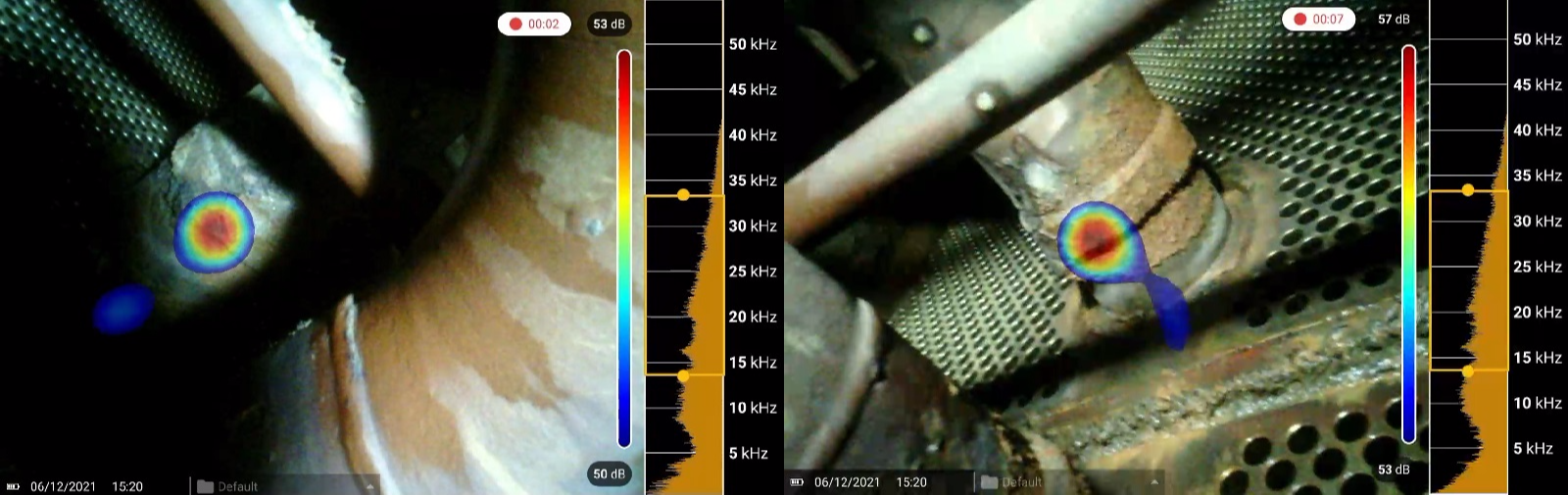

So, the task is to determine the place of air suction in the condensers after draining the cooling seawater. To do this, it is necessary to climb through the hatches into their sections and visually inspect the tube sheet and pipelines inside with a device. The video shows the result of the work done - the suction cup is found.

The reflection shows that the acoustic noise is directed towards the tube sheet. The reason is the corrosion of the welded seam due to degradation of the paint coating in sea water.

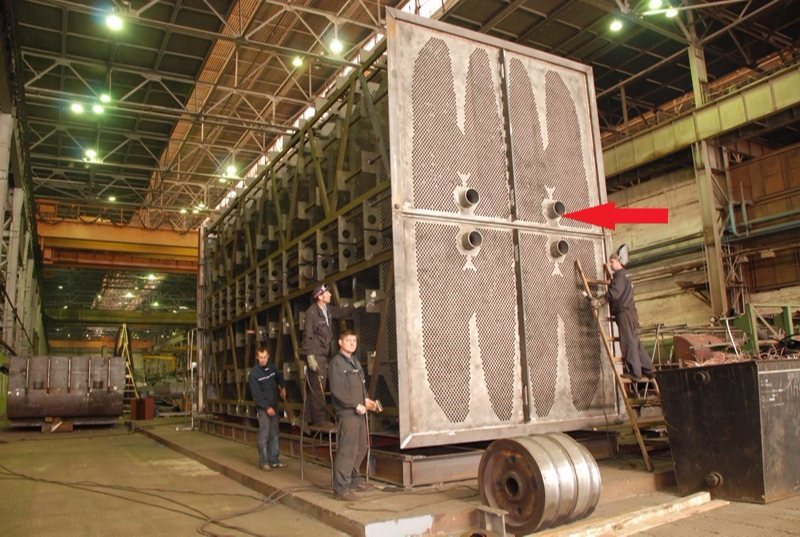

For a better understanding - the inside of the section of this condenser when it is manufactured at the factory: