Vibration diagnostics → Diagnostics of thrust bearings for the ЦНА 100-50-5 pump

Feb. 24, 2020, 2:59 p.m.Вибродиагностика, Дефекты подшипников

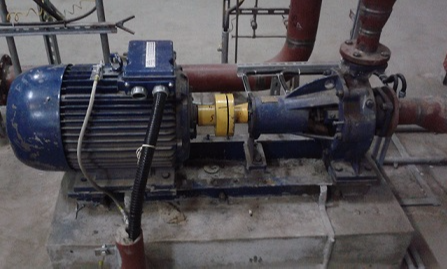

And again the vibration diagnostics showed its effectiveness. Today is another example from the practice of detecting defects in bearings. We have a TsNA pump 100-50-5, engine power 22 kW, 3000 rpm. Vibrocontrol is carried out once a month. The vibration of the bearing support with the thrust bearings 46-309 installed in it usually did not exceed 2 mm / s. At the next vibration control, a colleague revealed an increase in vibration velocity to 4 mm / s, reported a possible bearing defect and recommended replenishment of the lubricant.

Vibration diagnostics → Vibrodiagnostics of bearings of the pump 1K100-65-250

Feb. 23, 2020, 12:38 p.m.Vibration diagnostics → Vibrodiagnostics of screw pumps

Feb. 22, 2020, 8:55 p.m.I have seen a lot in my practice, I had to work with many equipment, but I did not encounter screw pumps. They are very expensive, including in maintenance, and, accordingly, are rare. And so it happened. The problem is immediately with two pumps Н1В 20/5 - 16/5 (N = 5.5 kW, n = 1440 rpm).

Vibration diagnostics → Extraneous fan noise

Feb. 22, 2020, 6:24 p.m.Посторонний шум, Вибродиагностика

One of the common reasons for calling a specialist in vibration diagnostics is noise from the unit. Sometimes the reasons are commonplace: a plastic bottle stuck between the fan blades (noise + vibration), lack of tightness of the door to the air conditioning fan chamber (whistling noise), faulty pressure valve in the ventilation network (periodic noise + vibration), etc. But more often, extraneous noise is a consequence of mechanical problems of the unit, which are the task of technical diagnostics to identify.

How to become an author?

Learn how to become an author and contribute to the techdiagnost.com community