Vibrodiagnostics of bearings of the pump 1K100-65-250

Вибродиагностика, Дефекты подшипников

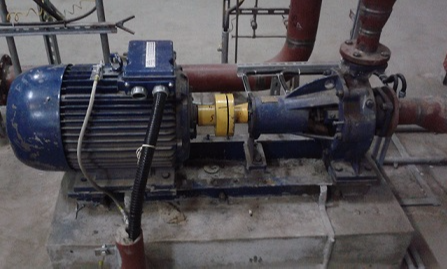

After almost a year of inactivity due to repair of valves on the pressure pipe, they called for the pump 1K100-65-250 to be turned on (N = 45 kW, n = 2940 rpm).

The operation of the unit is accompanied by a very strong extraneous noise, so I quickly take measurements (spectra of vibration velocity, envelope, as well as vibration acceleration and the time signal of the pump supports) and turn off the pump.

Measurement data (RMS vibration velocity in the range of 10-1000 Hz):

Tolerance in accordance with GOSTs and technical documentation for the pump 4.5 mm / s. We fix the excess.

Measurement data of vibration acceleration (RMS vibration acceleration in the range of 100-10000 Hz, m / s²):

As you can see, the pump bearings are a source of noise and vibration. For the sake of interest, I look at the measurement history of this unit (RMS vibration velocity in the range of 10-1000 Hz):

It can be seen that the first changes took place last spring and my colleague was missed. Now you need to analyze the spectra.

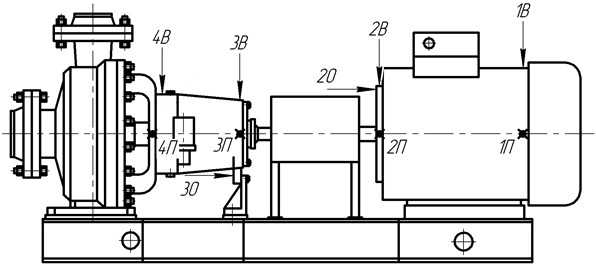

To identify the spectral components, the frequencies of bearings 6309 were calculated (on bearings No. 3 and No. 4, one such bearing was installed):

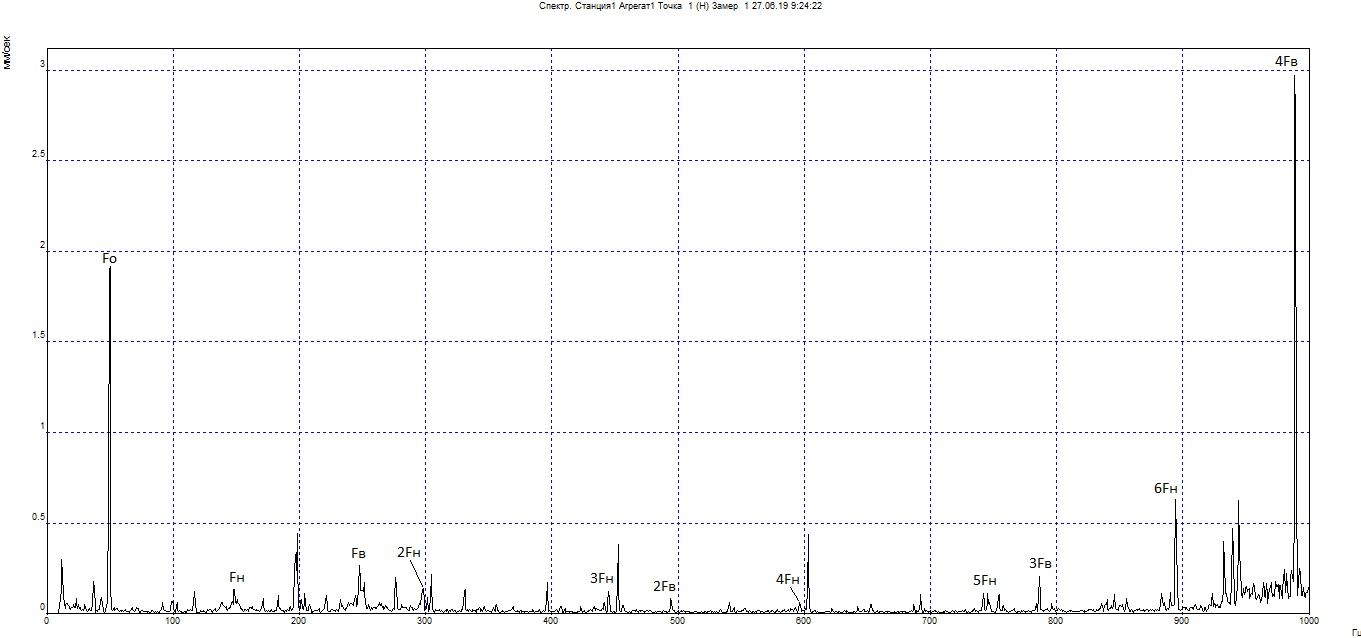

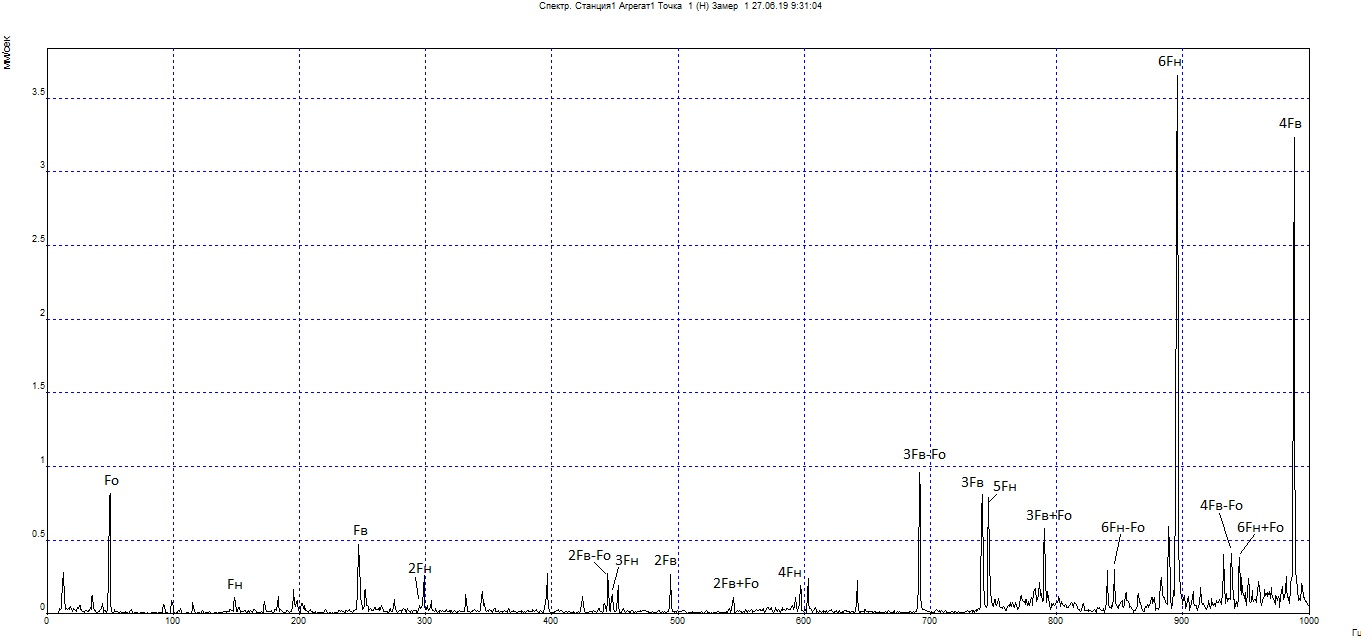

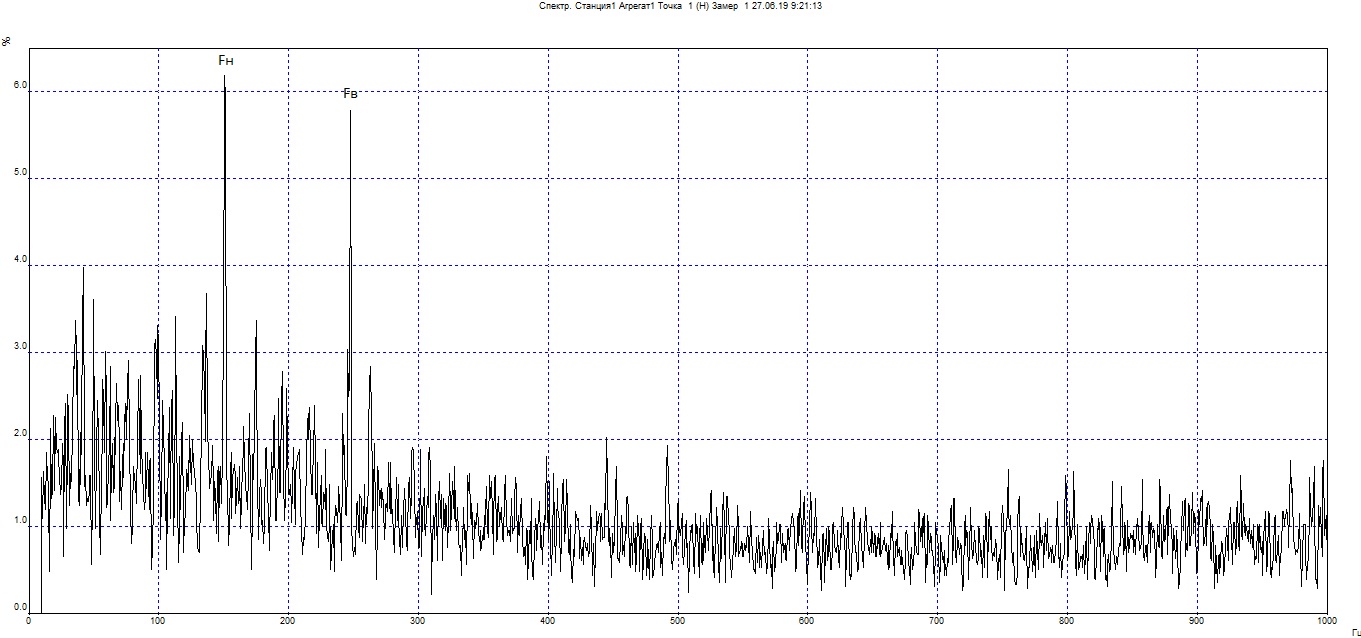

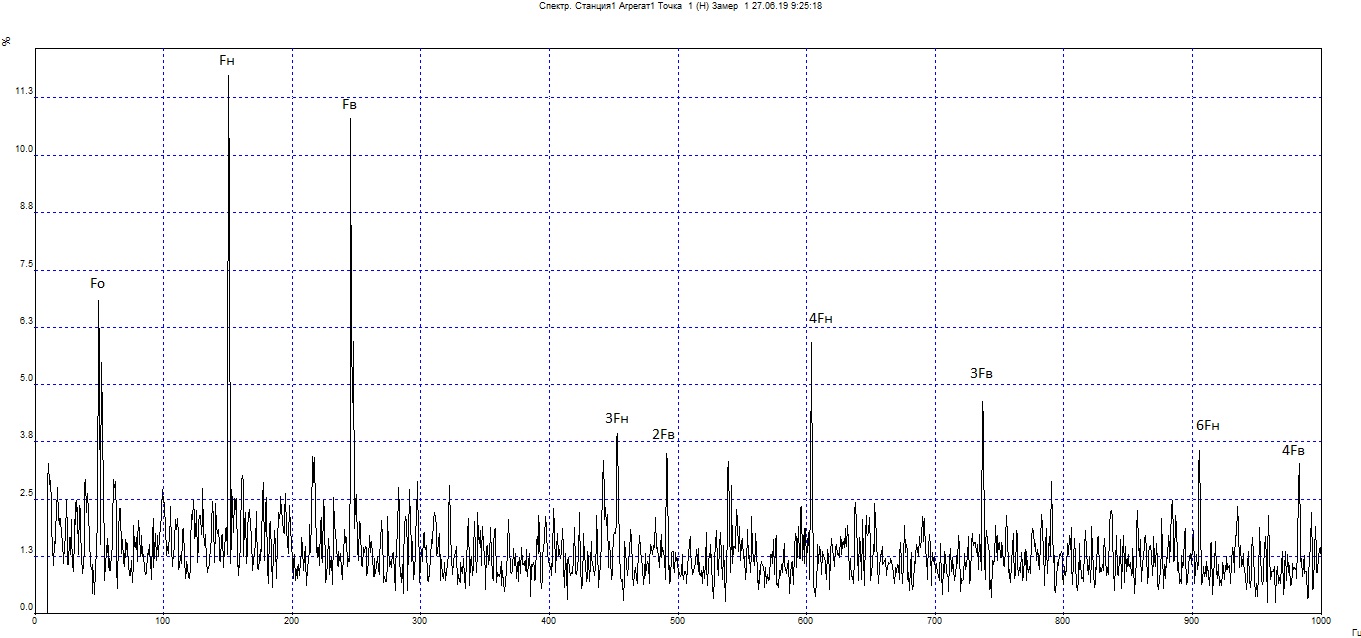

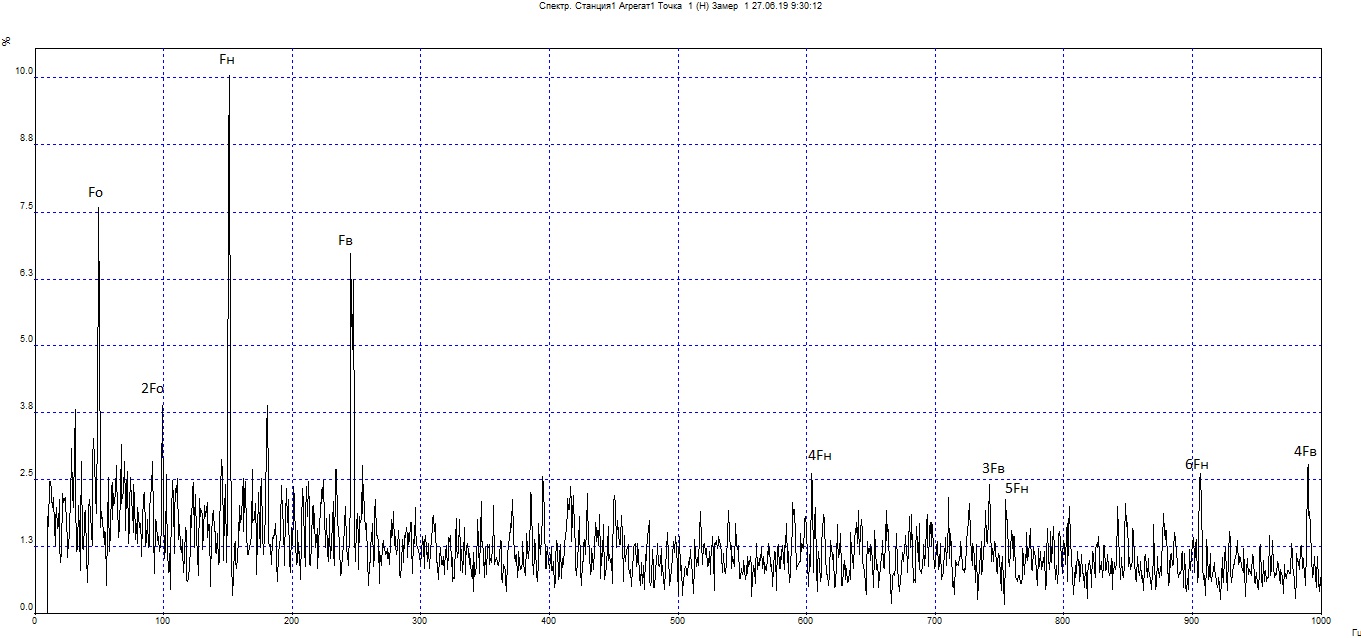

Spectra:

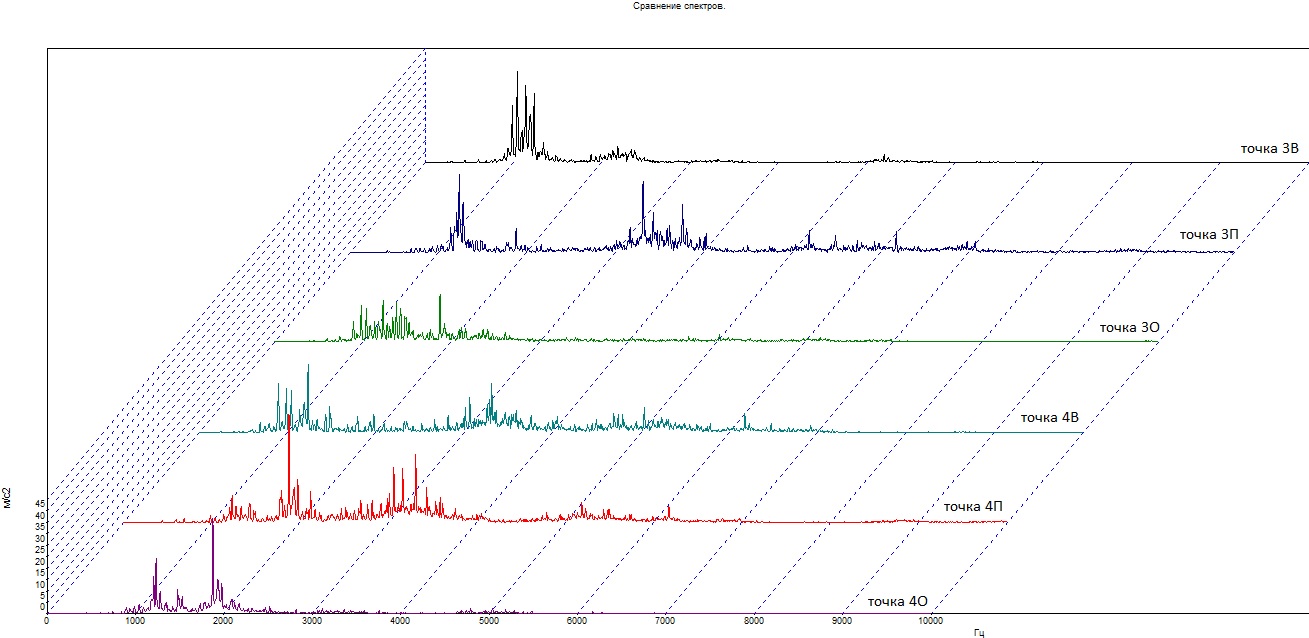

As you can see, in the direct vibration velocity spectra, bearing frequencies from defects on the tracks of the inner and outer rings of bearings dominate. Lateral components ± Fo are also noticeable, indicating deformations (shells) in the raceways. These components are also present in the spectra of the envelope of the vibration signal, but their amplitude is not high. The thing is that, you guessed it, the defect is very developed, and the vibration it causes has shifted from the high-frequency region to the low-frequency region. Therefore, for the diagnosis of such bearings, direct spectra of vibration velocity are sufficient. In confirmation of my words, I apply vibration acceleration spectra.

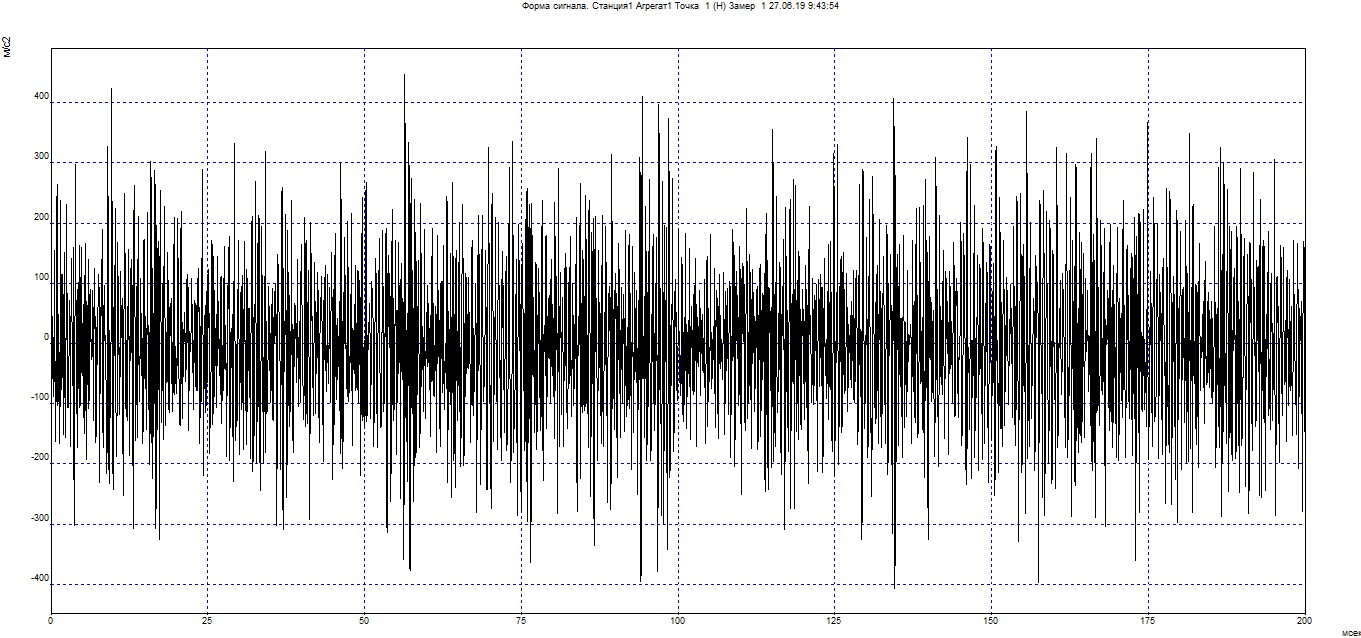

Impact pulses of these defects are clearly visible on the temporary vibration acceleration signal; pay attention to the range of vibration acceleration reaching 800 m / s².

Apparently there are a fair amount of defective places. It is not possible to single out any one defective bearing, it is very likely that there are problems on both bearings. Believe it weakly, this is extremely rare, but both are defective.

In the vibration control protocol I indicate the cause of defects in the inner and outer rings of bearings No. 3, 4, I recommend that the pump be put out for repair with the replacement of both bearings.

Two weeks later, the repairmen informed me that the bearings were removed, they can be picked up. According to them, only one bearing is defective. At the pump repair site, I performed an inspection of the bearings. The first thing that caught my eye was the terrible state of lubrication. Black-brown texture interspersed with some solid substances. Having rolled both bearings on a flat surface, I determine that there are defects on both (to my joy :)), I let the repairmen listen to the outgoing crunches and remove both bearings for analysis.

I disassemble, clean and share the photo with you.

Rubbing the bearings, I thought that these black spots were nothing more than coking grease. But no, rubbing it with a fingernail and then using a screwdriver I realized that it would not be possible to clean it off. Black spots - metal corrosion. The surface of the parts is damaged, sometimes very deep.

Apparently, the root causes of defects are the lack of maintenance (replenishment of grease during operation), long downtime without monthly testing of equipment.