Unusual bearing defect

After identifying bearing defects and taking the equipment for repair, we always try to pick up the dismantled bearings from the repairmen, disassemble them and inspect them in detail. Exotic cases are sometimes encountered along with standard faults. One of the recent ones will be discussed further.

ETANORM C 100-250 C11 pumps are very reliable. Problems arose only due to the human factor. But recently a colleague of mine diagnosed a pump malfunction - a defect in the inner ring of a closed bearing. Although the RMS vibration velocity levels were within tolerance, the sharp increase in vibration acceleration gave us every reason to recommend replacing the pump bearings.

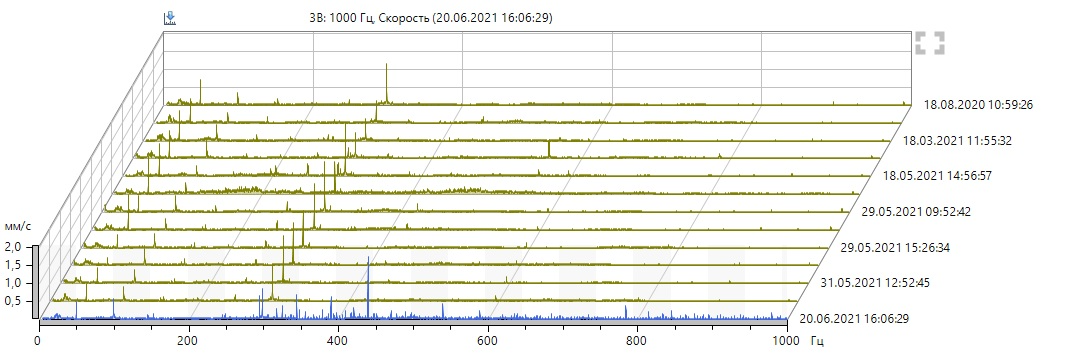

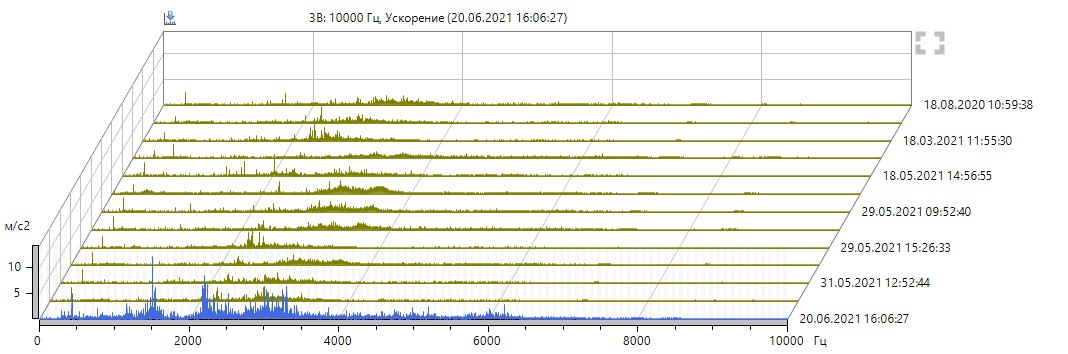

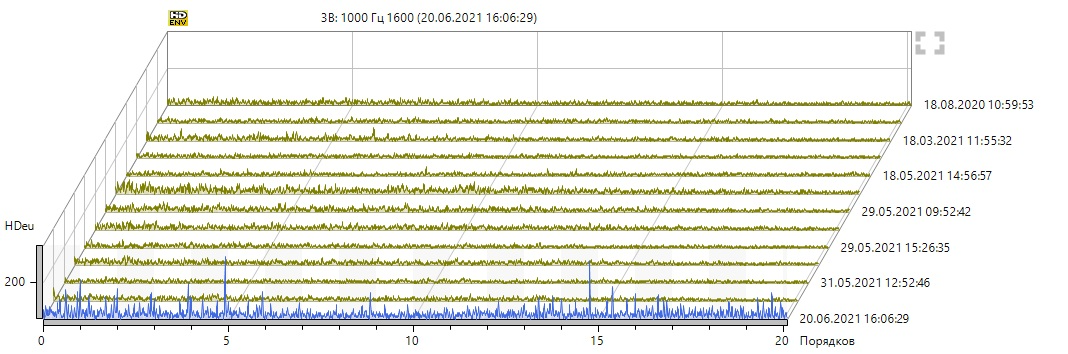

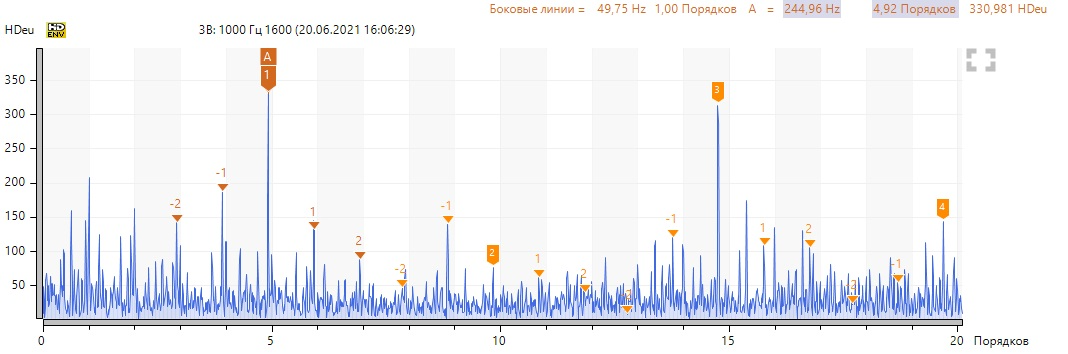

Consider changes in vibration spectra.

Bearing 6307 SKF. The rolling frequencies of the rolling elements on the inner ring of 244.96 Hz and their lateral +/- revolution frequency indicate a defect in the surface of the inner ring race. The spectrum also contains side separator (cage rotation frequency relative to the outer ring) and differential circulating and separator frequencies (rotor speed relative to the cage), which is typical for cage wedging when the rolling bodies pass through defective spots. These circumstances indicate the development of the defect.

Amplification of broadband noise in the vibration acceleration and envelope spectra indicates a lack or degradation of lubricant.

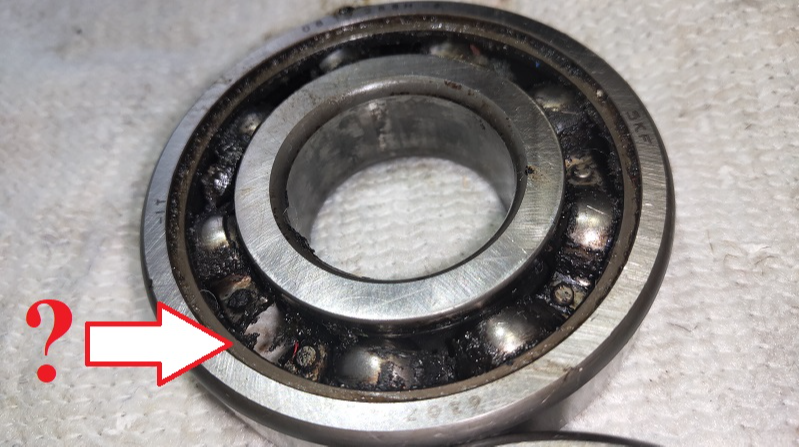

The results of the analysis were transferred to the owner's workshop and the pump was taken out for repair. Now let's look at the dismantled bearing. In addition to the complete degradation of the lubricant, a gap in the cage of the separator between the two rivets is striking.

One balloon missing? No. There are the same number of them as on the adjacent similar bearing.

This is the first time I've met such a defect. The pump is equipped with sealed bearings, so the pump manufacturer did not notice the problem. Another interesting fact is that the pump worked with such a bearing for more than 2 years and the defect did not manifest itself in any way.

Well, of course, a diagnosed defect in the inner ring.

I suspect that this is counterfeit, but I cannot think of how such a separator can be made.