Bending of the pump shaft CNSv 12.5-60

Виброналадка, Изгиб вала, Вибродиагностика

Bending of the pump shaft is rare. It can be determined by means of vibration diagnostics, and in some cases by simple inspection. In this article, we will consider a practical case of detecting this defect visually.

We have two pumps CNSv 12.5-60 with a capacity of 7.5 kW and a rotational speed of 3000 rpm. Both did not wait for adjustment after installation due to the lack of availability of the technological system. Years passed and finally the moment of their testing came. One of them did not pass by vibration. Let's start the analysis.

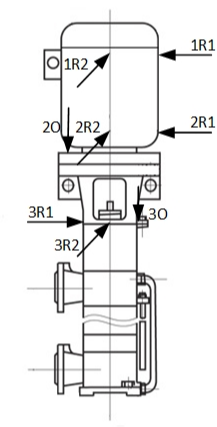

Pump diagram showing measuring points:

According to the factory documentation, vibration tolerance is 3.0 mm / s. RMS vibration velocity (mm / s) in the range of 5-1000 Hz:

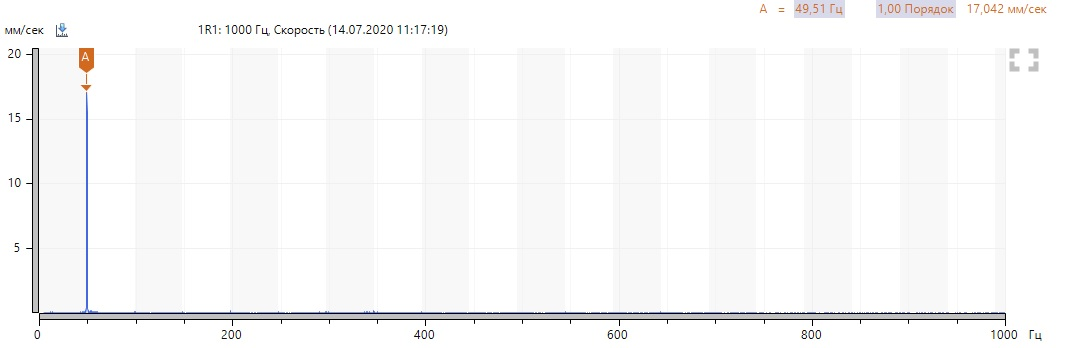

There is nothing special to analyze. Vibration velocity spectrum at point 1R1:

All vibration is concentrated at a revolving frequency of 49.51 Hz. First thoughts are resonance or imbalance. While the pump is running, I press on the electric motor - the vibration drops slightly, there is no resonance. It would be nice to inspect the clutch. I take out the stroboscope, set its frequency close to the rotation frequency (so that the shaft visually rotates slowly) and proceed to the inspection:

It can be seen that on one side of the coupling the rubber is skewed, the gap between the coupling halves is different. We are allowed alongside and on the disassembled electrical circuit, we inspect the half-coupling for the presence of a battle:

Fight of the clutch is present. To determine exactly which half of the coupling is the source of the battle, remove the electric motor and repeat the procedure:

The defect is even more visible without the motor coupling half. The reason is the bending of the pump shaft. This completes the work and the pump was handed over to the repairmen. The repair personnel confirmed the defect - a bend at the very end of the rotor after its threaded part. It is not difficult to guess that the human factor is its cause. The windows in the area of the coupling are small and someone hammered the pump coupling half onto the shaft through the window, being too lazy to perform the installation in a less barbaric way.

The shaft has been aligned (according to the repairmen, the residual deflection is 0.03 mm) and the pump is ready for testing after repair. RMS vibration velocity (mm / s) in the range of 5-1000 Hz:

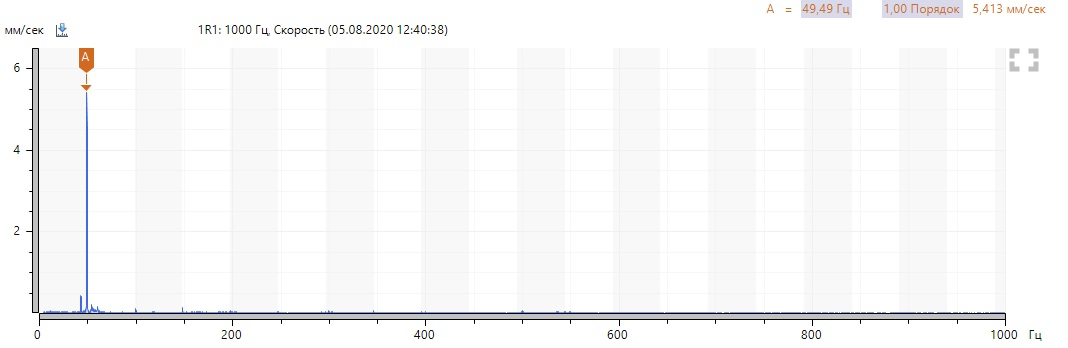

Vibration velocity spectrum at point 1R1:

Further, the pump assembly was easily rebalanced by installing a few grams on the blower impeller of the electric motor. RMS vibration velocity (mm / s) in the range of 5-1000 Hz after balancing:

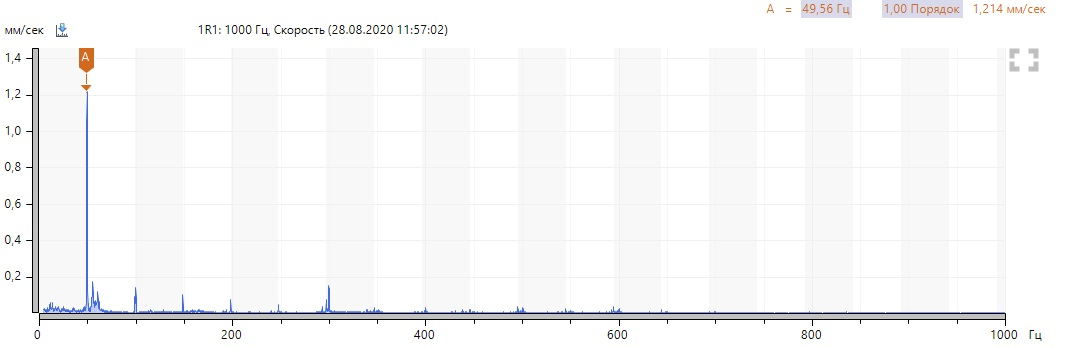

Vibration velocity spectrum at point 1R1 after balancing:

This completed the work.